6 hours.

Today was spent tidying some wing attach stuff. I got my order from ACS, so I was able to finish installing and torquing all the wing attach hardware. I also did the fuel line on the left tank, remembering this time to put the rubber grommets on before flaring the ends. There’s a $30 tool that will stretch those rubber grommets out so you can get them over flares and fittings, but I figure it’s good practice just to try to be less stupid.

The most interesting part of the day was the short flight I took in my hangar mate’s Luscombe.

I’m not sure which model this is, but I think it’s an 8C or 8D. It burns 4 gallons per hour, which is probably about half of what the Pipers I learned on did. It has no flaps, no lights, and only the minimum equipment of single radio and transponder to get around Southern California’s interesting airspace.

Now, I’ve never been in, much less flown a taildragger, and the oldest airplane I’ve even sat in was an old L-19 Bird Dog in Ft. Leavenworth KS when I was a little kid. This aircraft was built some time during the early 1940’s, and Ron was kind enough to let me follow him on the pedals to get a feel for the quirks of a taildragger. This shot is one out the right window, us taxiing to runway 22 at OXR.

And another out the front.

And another out the front.

The instrument panel is simplicity itself. Everything you need for day VFR, nothing you don’t. The mount for the Garmin 296 GPS looks strangely out of place, over to the side out of frame. There’s a single vernier cable control for throttle and a small one for carb heat. I didn’t see one for mixture. I don’t think there is one. The fuel gauge is on the bulkhead behind me, between the two seats.

We did a landing at Santa Paula, where I was able to get a picture of Steve McQueen’s old hangar. I love this airport already. I just wish we’d had the chance to buy McQueen’s old ranch when it popped up on Jalopnik last year and it was dangerously close to something we could afford at its fire-sale price.

We did a landing at Santa Paula, where I was able to get a picture of Steve McQueen’s old hangar. I love this airport already. I just wish we’d had the chance to buy McQueen’s old ranch when it popped up on Jalopnik last year and it was dangerously close to something we could afford at its fire-sale price.

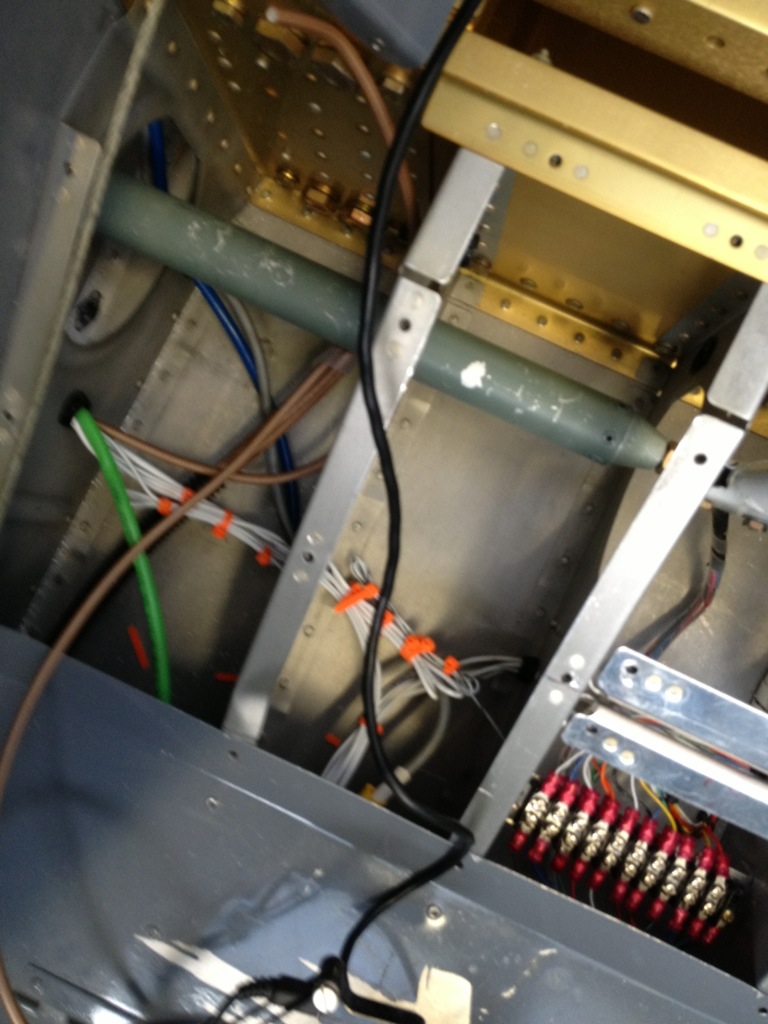

That adventure only took about 20 minutes to half an hour. When I got back, I did most of the real work. Here’s the right flap, on and conneted. There’s some more rigging to be done, and some more wiring, but the wings are nearly fully on and connected. I also got the left rudder pedal connected to the cable, but ran out of time before I could do the right one. I’ll hit that in a week. Soon it will be time to mount the prop!

That adventure only took about 20 minutes to half an hour. When I got back, I did most of the real work. Here’s the right flap, on and conneted. There’s some more rigging to be done, and some more wiring, but the wings are nearly fully on and connected. I also got the left rudder pedal connected to the cable, but ran out of time before I could do the right one. I’ll hit that in a week. Soon it will be time to mount the prop!