OK, so I’m getting back into the training kit. First full weekend I’ve had in several months. If anybody says to you that doing CGI FX is a cakewalk, think of something anatomically impossible and tell them to try it. It takes your time and your life, makes you fat and turns your hair gray. But I was able to sneak away this weekend (since my stuff’s done anyway) and try to get as far with this kit as I can.

Today we unleash the full power of the radial drill press upon these aluminum parts. The first two pictures show how this thing will contort to match non-square angles. It really makes this stuff easy and I can lay off the air drill for a while.

Head angled, piece clamped to articulated table.

Closeup. I love this thing.

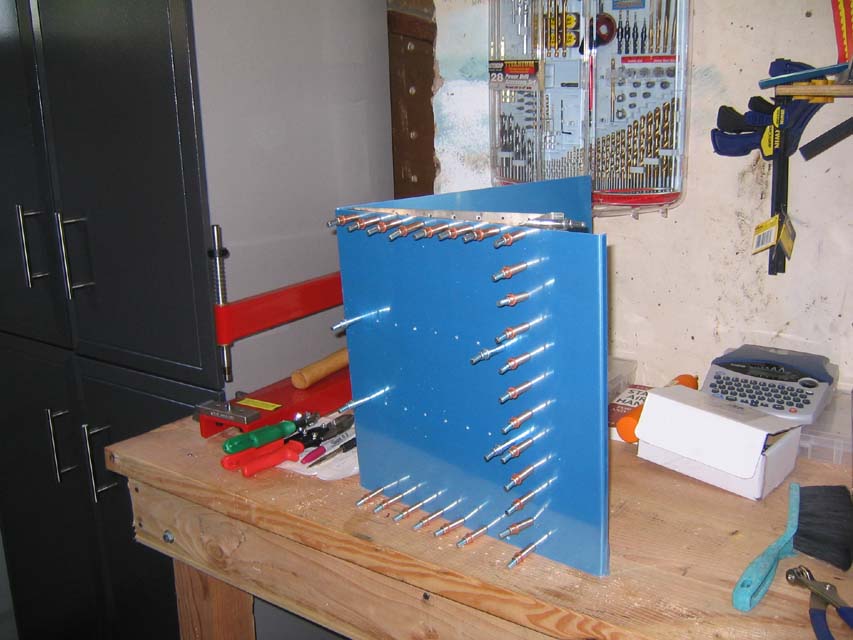

The toolfest doesn’t stop there. Here’s the rivet spacer fan in action:

Notice how it’s way too long. I might order the 10-hole one from ACSpruce next time I need something, which is now. More on that later.

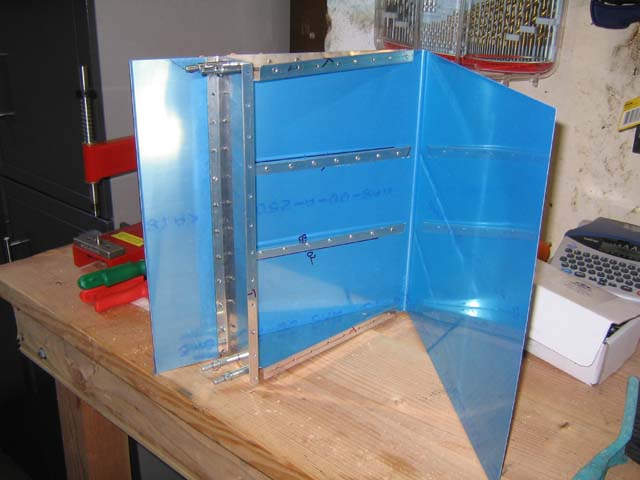

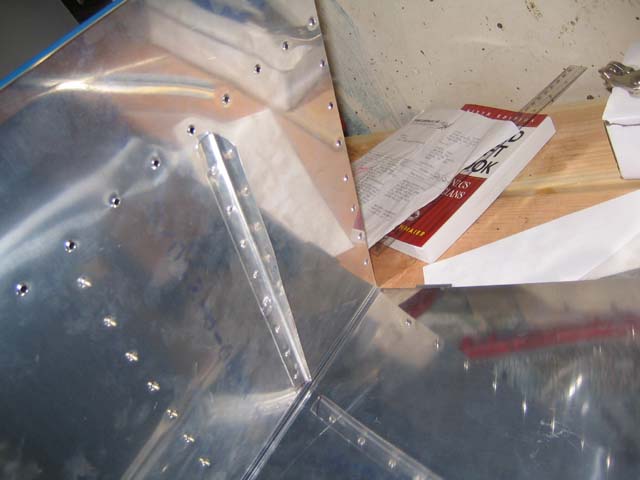

Here’s the spar and ribs drilled and deburred, ready for clecoing.

And here’s the skin clecoed to the ribs and spar.

Who’s the dork and what’s he doing? Oh. I see. HE’S BUGGERING UP THE RIBS AND SKIN! STOP HIM!

Too late. Although this looks fine, Yours truly managed to drill the holes in the ribs with a #30 instead of a #40. So this means the skins get riveted to the spars with 1/8″ rivets instead of 3/32. Not a big deal, but definitely a big oops.

FIRST RIVETS EVER! Woohoo! Yay!

Shit.

This is what happens when you dont’ have a back-rivet plate and you try to use a big bucking bar under the skin instead. The work slipped off the bar and the back-rivet set dinged the crap out of the skin and stiffener. Looks like I’ll be bookmarking the replacement part page at Van’s Aircraft.

Yeah, big badda boom. Totally dinged. Discouraging, but not enough to make me seriously consider 7 years of sanding.

One more for good measure. Ouch!

So what did we learn today? Well, for one thing, Home Depot doesn’t have quarter-inch steel plate. Doesn’t have it in any form, other than with something non-aircraft-useful welded to it. Another thing is that trying to cross-purpose tools that don’t like to be cross-purposed will sometimes result in damage. Had this been an actual airplane, the little adventure with the skin and the stiffener would have necessitated ordering a new skin and fabbing a new stiffener. Same with drilling the rib holes out to the wrong size. That’s the problem with repetitive production made easy: you don’t realize you’ve screwed up until you’ve screwed up a whole lot.

It wasn’t all bad, though. Riveting the stiffeners to the skin was OK, except for that one event, and from what the AC Handbook says, they’re good rivets.

We also found out later that it’s probably not cool to run a rivet gun at 11:30pm. It’s freaking loud, especially with the garage door open. My next door neighbor has a concrete block wall between my garage and her house, but I need to think about soundproofing. Moderately effective at best, a complete waste of time at worst. I need to do a sound check, but that involves having somebody in there running the gun while I walk around and check the noise levels.

« Archives in April, 2005