19 hours.

Yeah, that’s Thursday, yesterday, and today.

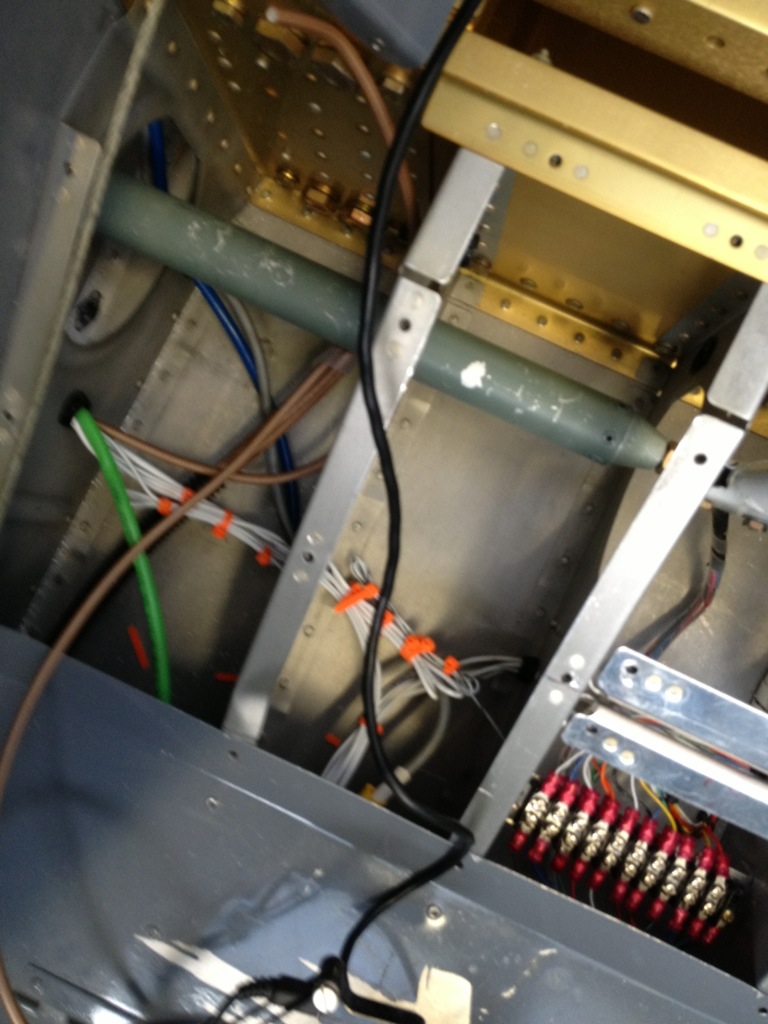

The pieces are going on the plane now. I installed both wingtips and did the accompanying wiring. Of course, like a moron, I severed the GPS antenna wire while I was crimping a connector for the wingtip VOR antenna, but Jim had an extra one and I was able to repair the GPS cable and install the VOR antenna cable

I also installed the strobes and new strobe pack. The bright white flash is the strobe actually working in the left wingtip.

One of the neat things about Oxnard airport (and presumably Camarillo) is that you often get treated to flybys of things like this restored B-25. Weird stuff passes by outside my hangar just about every day, and I love it.

This is the wingtip, showing the landing light and nav light working.

This is the wingtip, showing the landing light and nav light working.

Both wingtips on here. I spent a little time peeling the remaining blue stuff off the tail, and I just need to get it off the bottom wing skins and the plane will be blue-stuff-free.

Both wingtips on here. I spent a little time peeling the remaining blue stuff off the tail, and I just need to get it off the bottom wing skins and the plane will be blue-stuff-free.

Hoisting the prop out of the shipping crate, hopefully for the last time.

Hoisting the prop out of the shipping crate, hopefully for the last time.

Prop is on!

Prop is on!

Today was about the prop. I tried to get it done yesterday, but there was a flight, a barbecue, and the need to get home for evening plans, so I wound up doing it today. Today was not all that wonderful. There was an accident at the airport and I don’t have any details, and won’t publish them here until more is known, but it appears that we’ve lost a really good guy and a wealth of knowledge of experimental aviation and RV’s in particular. Yesterday he lent me a torque wrench so I could torque the prop bolts, which I did today, along with the spinnner.

Today was about the prop. I tried to get it done yesterday, but there was a flight, a barbecue, and the need to get home for evening plans, so I wound up doing it today. Today was not all that wonderful. There was an accident at the airport and I don’t have any details, and won’t publish them here until more is known, but it appears that we’ve lost a really good guy and a wealth of knowledge of experimental aviation and RV’s in particular. Yesterday he lent me a torque wrench so I could torque the prop bolts, which I did today, along with the spinnner.